● PJW-10II mainly consists of load frame, computer control unit, heavy-current control unit, test attachment, etc..

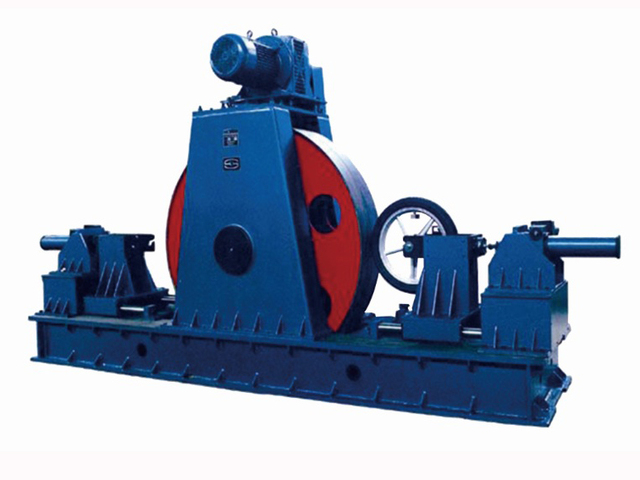

● The load frame adopts welding structure design, horizontal loading, big drum adopts international standard to design, design diameter 1707mm, realistic simulation the status of road surface, variable frequency speed-adjusting motor drives drum to realize stepless speed-adjusting, further to realize test under different driving speed. Loading frame adopts low damping linear part drive, and servo motor drive closed-loop control, to make load cell completing the measurement to loading force, so as to realize closed-loop control of fatigue test load, as well as realize the function of emergency stop of wheel drum fatigue damage.

● The test process is automatically controlled via computer. After the test load, test miles are set up via computer, computer will control servo motor to load automatically, and auto stop when reach test miles.

● Computer control system equips safety protection, when over load, burst, wheel damage, etc. contingency happen, the machine will unload and stop automatically.

● Configured with heavy-current control box to complete drive control of excitation speed-adjusting motor, it has the function of power on, power off, motor start, motor stop, increase and decrease of rotation speed.

● The servo controller and computer complete test control and operation. The computer software is on WINDOWS basis, with the function of test parameters setting, dynamic test waves display, test data store, output test report, etc..

● The report can be printed by printer.

Standards

It meets the standards of QC/T211-1996, QC/T212-1996, JASO T 203-85, ISO8644-1988, ISO8645-1988, GB/T6147-92.

Applications

It is mainly used to do rolling bend fatigue testing of Motorcycle or Light Motorcycle.

Đánh giá

Chưa có đánh giá nào.